Effect of high energy Ar-ion milling on surface of quenched low-carbon low-alloyed steel

Tibor Berecz1, a, Szilvia Kalácska2,b, Gábor Varga2,c, Zoltán Dankházi2,d, Károly Havancsák2,e

1 Budapest University of Technology and Economics, Department of Materials Science and Engineering

1111 Budapest, Bertalan Lajos utca 7., Hungary

2 Eötvös Loránd University, Department of Materials Physics

1117 Budapest, Pázmány Péter sétány 1/a.

Abstract

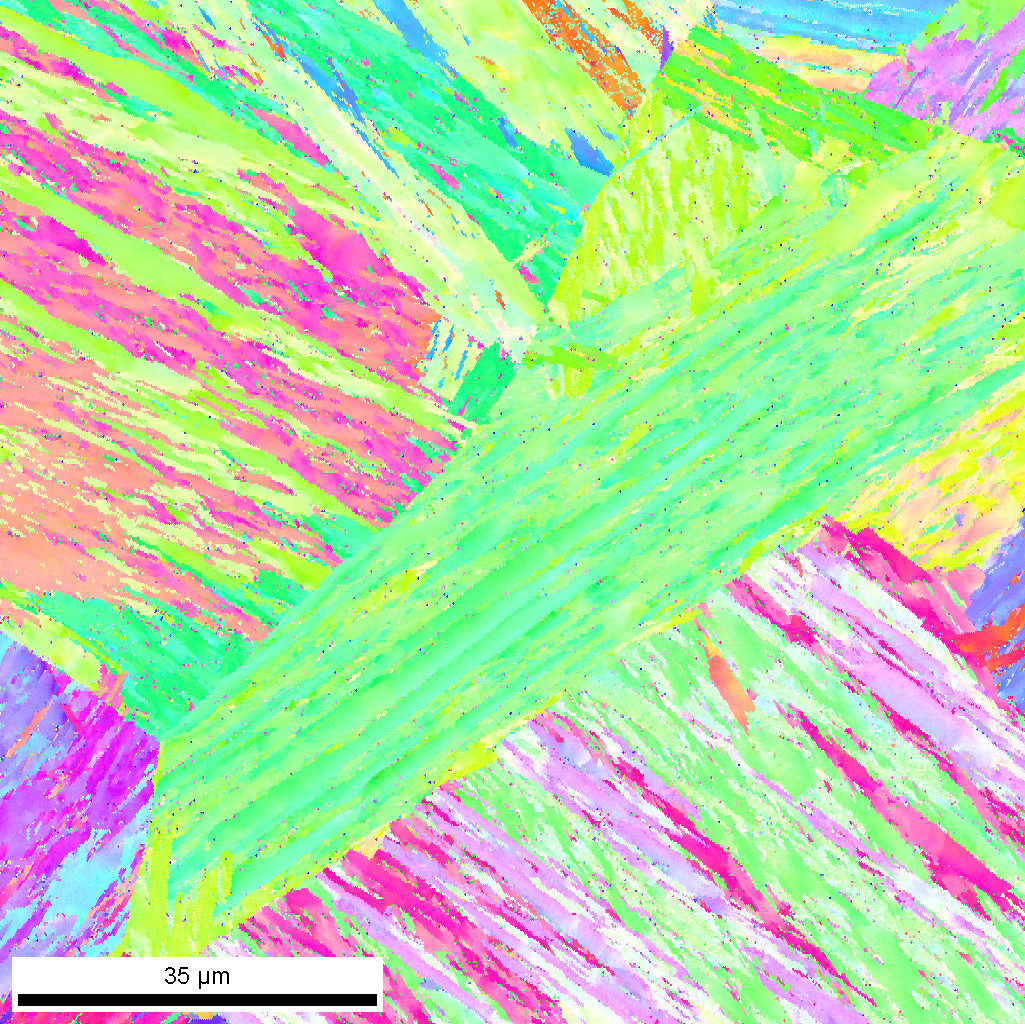

Surface preparation for electron backscatter diffraction (EBSD) measurements requires a lot of time and experience. We chose a lath martensitic iron based alloy to demonstrate the efficiency of ion polishing techniques. The average image quality (IQ) values from the EBSD measurements were assigned to be the characteristic parameter for surface goodness. The ideal ion sputtering time and the angle of incidence were determined, and the corresponding inverse pole figure (IPF) and IQ maps were compared to the mechanical polishing treatment.

Material Science Forum Vol. 812 (2015) pp 285-290

Doi: 10.4028/www.scientific.net/MSF.812.285