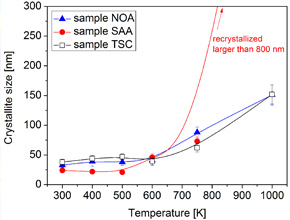

The effect of bath additives on the thermal stability of the microstructure and hardness of nanocrystalline Ni foils processed by electrodeposition was studied. Three samples with a thickness of 20 μm were prepared: one without any additive and two others with saccharin or trisodium citrate additives.

Weak-beam scanning transmission electron microscopy for quantitative dislocation density measurement

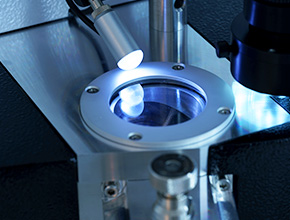

To evaluate dislocations induced by neutron irradiation, we developed a weak-beam scanning transmission electron microscopy (WB-STEM) system by installing a novel beam selector, an annular detector, a high-speed CCD camera and an imaging filter in the camera chamber of a spherical aberration-corrected transmission electron microscope.

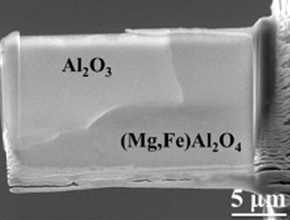

Focused ion beam (FIB) sample preparation technique in plan-view geometry allows direct correlations of the atomic structure study via transmission electron microscopy with micrometer-scale property mea- surements.

The high resolution scanning electron microscope is a versatile tool for nanotechnology and advanced materials science, moreover, opens up new dimensions in archaeology, biology, earth science, meteorite research, hydrology and many other research areas.

For the large majority of materials science studies a good quality surface is extremely important. Especially it is of great importance in the case of EBSD sample preparation where the information depth is as shallow as some tens of nanometres and this is the reason why it requires a damage- and oxide-free surface. The SC-1000 SEMPrep dual Ar beam...

Sample preparation plays a crucial role in any investigation and it is particularly true for electron backscatter diffraction (EBSD) measurements. In this technique the information depth is as shallow as some tens of nanometer and this is the reason why this method requires damage- and oxide-free sample surfaces. There are a number of techniques to prepare specimens for EBSD...

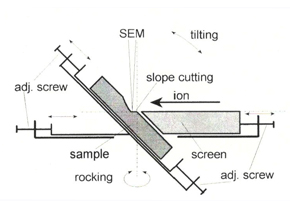

Possibility of surface polishing. The geometrical model of surface topography. Rotating sample. Rocked sample movement. Preferential sputtering. Tools and parts for sample preparation for ion beam thinning. Arrangements of ion milling. Ion beam sample preparation for cross-sectional TEM. Artefacts due to ion beam milling. Sample temperature during ion sputtering. Ion beam slope cutting.

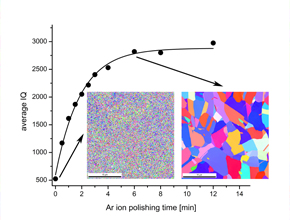

Surface quality development on series of metal samples was investigated using a new Ar ion milling apparatus. The surface quality of samples was characterized by the image quality (IQ) parameter of the electron backscatter diffraction (EBSD) measurement. Ar ion polishing recipes have provided to prepare a surface appropriate for high quality EBSD mapping. The initial surfaces of samples were roughly grinded and polished. High quality surface smoothness could be achieved during the subsequent Ar ion polishing treatment. The optimal angles of Ar ion incidence and the polishing times were determined for several materials.

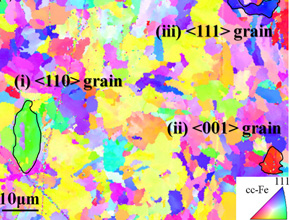

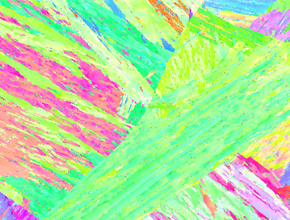

Surface preparation for electron backscatter diffraction (EBSD) measurements requires a lot of time and experience. We chose a lath martensitic iron based alloy to demonstrate the efficiency of ion polishing techniques. The average image quality (IQ) values from the EBSD measurements were assigned to be the characteristic parameter for surface goodness. The ideal ion sputtering time and the angle of incidence were determined, and the corresponding inverse pole figure (IPF) and IQ maps were compared to the mechanical polishing treatment.