EBSD sample preparation: high energy Ar ion milling

Zoltán Dankházi1,a, Szilvia Kalácska1,b, Adrienn Baris1,c, Gábor Varga1,d, Zsolt Radi2,e, Károly Havancsák3,f

1 Eötvös Loránd University, Department of Materials Physics

Hungary, 1117 Budapest, Pázmány Péter sétány 1/a.

2 Technoorg Linda LTD. CO.

Hungary, 1044 Budapest, Ipari Park utca 10.

3 Eötvös Loránd University, Faculty of Science Research and Instrument Core Facility

Hungary, 1117 Budapest, Pázmány Péter sétány 1/a.

Abstract.

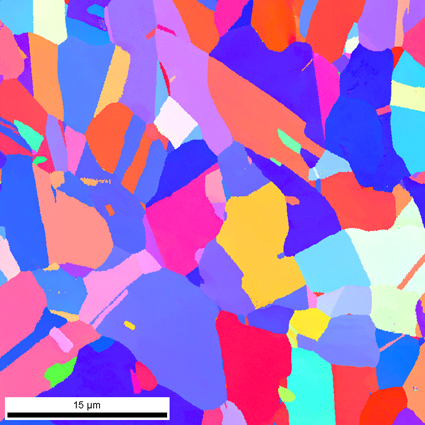

Surface quality development on series of metal samples was investigated using a new Ar ion milling apparatus. The surface quality of samples was characterized by the image quality (IQ) parameter of the electron backscatter diffraction (EBSD) measurement. Ar ion polishing recipes have provided to prepare a surface appropriate for high quality EBSD mapping. The initial surfaces of samples were roughly grinded and polished. High quality surface smoothness could be achieved during the subsequent Ar ion polishing treatment. The optimal angles of Ar ion incidence and the polishing times were determined for several materials.

Material Science Forum Vol. 812 (2015) pp 309-314

Doi: 10.4028/www.scientific.net/MSF.812.309