Preparation techniques for grain structure evaluations

Here is a quick summary of the topics covered:

Methods for grain structure investigation using SEM:

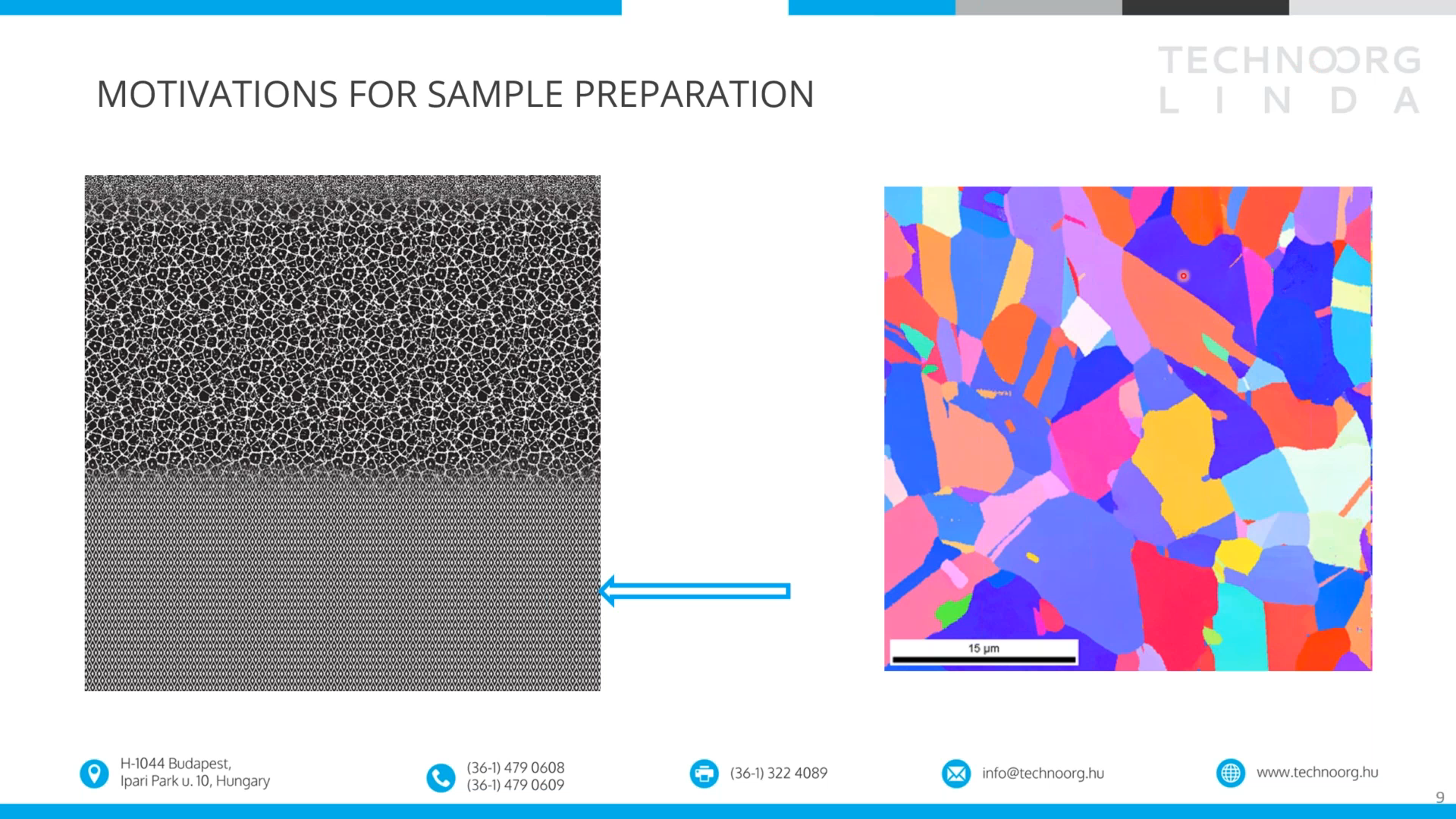

Electron Backscatter Diffraction (EBSD) is probably the best and most common method for characterizing polycrystalline materials. However, grain structure can also be observed under ETD or BSED detectors due to the orientation contrast, provided the surface quality is sufficiently high.

Sample preparation objectives:

Mechanical sample preparation is in most cases inevitable but results in the formation of a deformed, amorphous layer on the surface of the material. Removal of this layer is crucial to obtain a good quality, not falsified grain structure image and can be accomplished through ion milling.

Comparison of preparation techniques:

There are several methods to improve the surface quality of the sample, such as refined mechanical polishing, chemical etching, electropolishing, or post-processing among others, but each method has its limitations.

Broad beam ion milling:

Compared to other methods, ion milling stands out thanks to its versatility concerning the type of material, the relatively large treated area, and the overall short speed of the process.

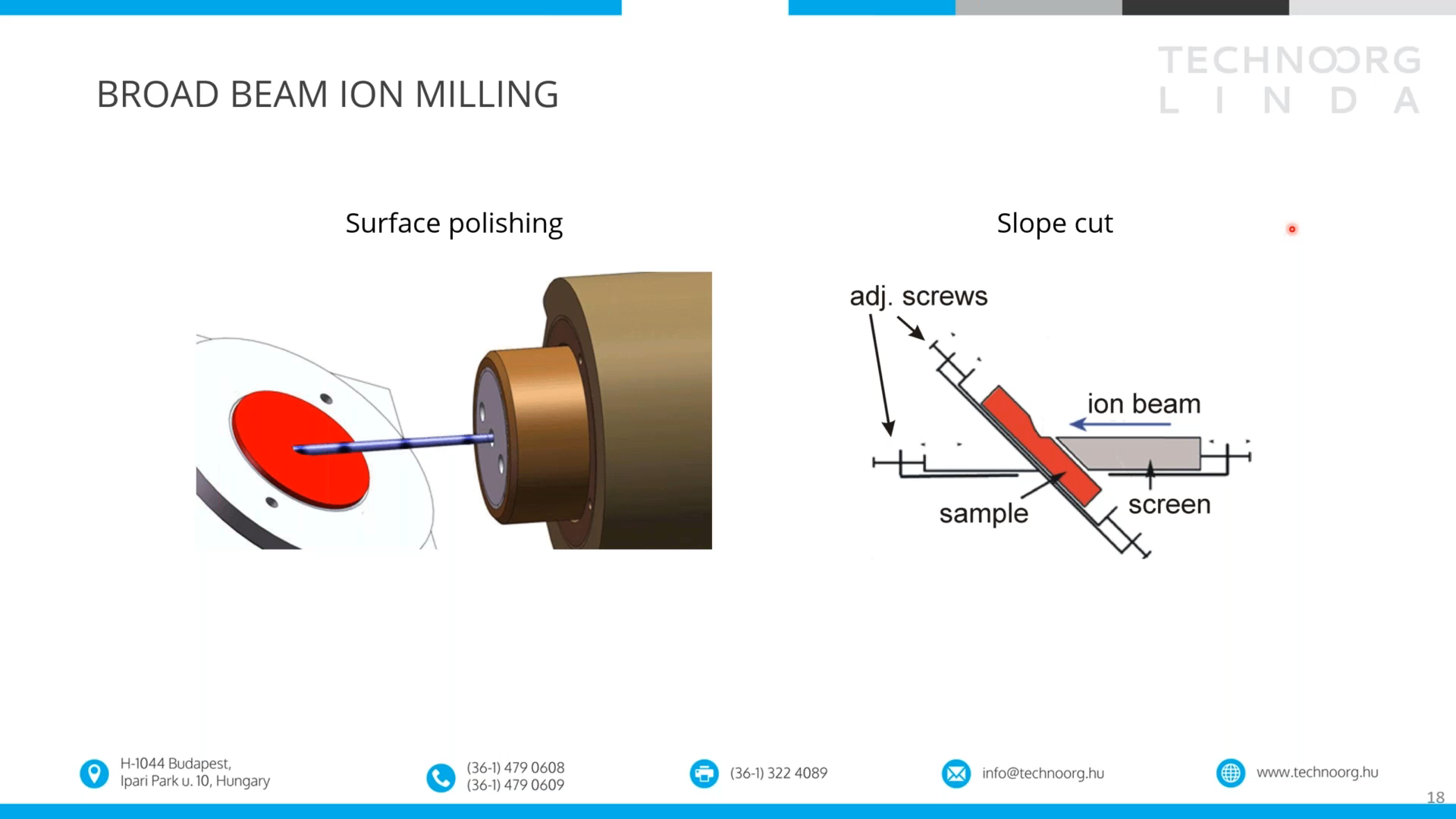

Broad beam ion milling

Grain structure evaluation on various samples:

Surface polishing and slope cutting are the two ways of using ion milling technology to obtain EBSD-ready surfaces on various samples, including inhomogeneous materials, porous materials, thin films, and wire samples.